Products

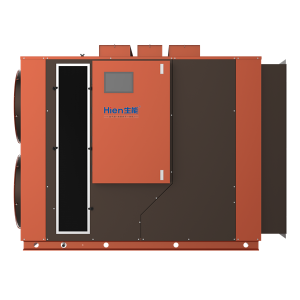

All-in-One Air Source Heat Pump Dryer

Product parameters

| Product name | Open All-in-One Air Source Heat Pump Dryer |

| Model | DRP20D/02 |

| Power supply | 380V3N~50Hz |

| Anti-shock level/protection level | IP×4 Class I/IP×4 |

| Rated calories | 20000W |

| Rated power consumption/working current | 6500W/13A |

| Maximum power consumption/working current | 9750W/19.5A |

| Electric heating rated power consumption | 12000W |

| Electric heating rated working current | 20A |

| Drying room temperature | 20-75℃ |

| High/low pressure side maximum working pressure | 3.0MPa/3.0MPa |

| Maximum working pressure on discharge/suction side | 3.0MPa/0.75MPa |

| The maximum pressure of the evaporator | 3.0MPa |

| Noise | R134a (3.1x2)kg |

| Refrigerant charge | R134a 4.4kg |

| Dimensions (L×W×H) | 1650×1400×1300(mm) |

| Net weight | 370kg |

| Drying room volume | 24m³ Below24m³ |

Features

1. The operation management of the unit is automatically completed by a microcomputer and controlled by a touch screen;

2. The unit adopts multiple waste heat recovery, preheats the fresh air, and uses the waste heat of moisture exhaust to increase the evaporation temperature of the evaporator at low temperature;

3. With WIF| function;

4. The forward and reverse function of the large circulating fan is integrated;

5. The integrated design of indoor and outdoor units adopts a three-fan structure, one external fan, two outlet fans, and three waste heat recovery fans;

6. Defrosting system: intelligent defrosting;

7. Adopt electronic expansion valve throttling technology to ensure the stability of each working condition;

8. Adopt low-temperature supplemental gas and enthalpy increase technology;

9. The return air temperature can reach up to 80℃;

10. The unit is mainly used in the area where the minimum ambient temperature is -10℃~43℃.

Application field

Air source heat pump dryers are widely used in three major industries, which can be subdivided into many categories, especially the primary industry. According to the national economic industry classification, the sub-categories of heat pump drying applications in the primary industry agriculture include grains, tobacco, fruits and vegetables, edible fungi, flowers, tea, Chinese herbal medicines and aquatic products; the secondary industry industrial manufacturing heat pump drying application categories involve Printing, leather manufacturing, fireworks manufacturing, electroplating industry. Air source heat pump drying technology has been widely used in hotel services in the tertiary industry and in the sludge treatment industry in public facility management.

Pepper drying

Heat pump drying method for peppers: The water content of pepper raw materials is very high, generally 75%^85%. Set the temperature of the Quaneng pepper dryer to 40℃-60 ℃ hot air drying, the relative air temperature is lower than 70% at first, and the relative air humidity drops to 52% after 5 hours, and after 2 hours, the relative air humidity is all lower than 40%. Therefore, the productivity of pepper drying operation is mainly determined by the temperature of the pepper itself, rather than the ability of hot air to carry and remove moisture. From the perspective of ensuring that the nutrients of peppers are not affected after drying and improving productivity, the temperature of the hot air for drying peppers is determined by 60 ℃ - 70 ℃ C is suitable.

Staged drying is currently the preferred method for drying peppers, that is, peppers with a moisture content of 75% to 85% are first dried to a moisture content of 50%, and then the second time is dried. After the second drying is completed, high-quality dried chili products can be obtained